Introduction

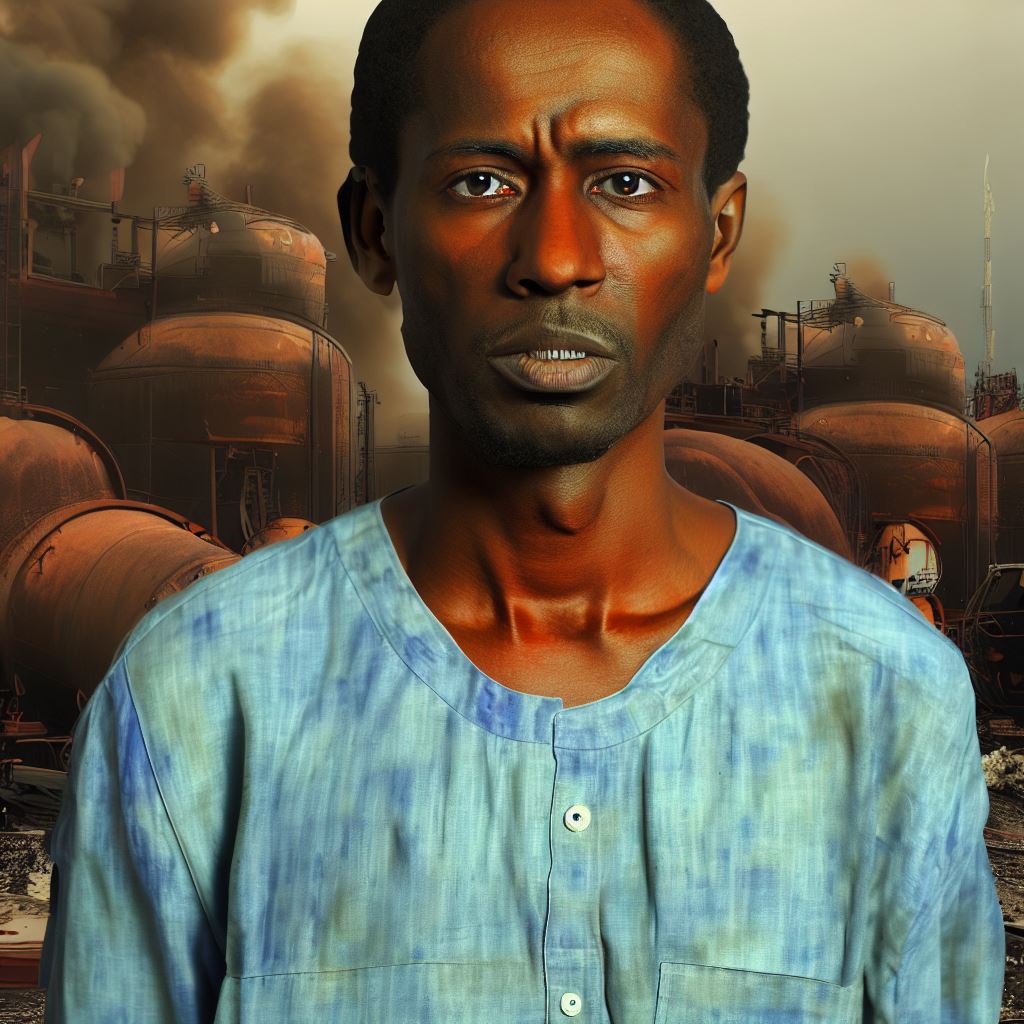

Safety is a crucial aspect when it comes to the transportation of hazardous materials, especially in Nigeria’s rail system.

This blog post will discuss the significance of safety protocols for tank car loaders in Nigeria’s rail and preview the main points to be discussed.

Importance of safety protocols for tank car loaders in Nigeria’s rail

Ensuring the safety of tank car loaders in Nigeria’s rail is essential to prevent accidents, protect lives, and minimize environmental damage.

Following safety protocols can significantly reduce the risk of incidents, ensuring the smooth operation of rail transportation.

Preview of main points to be discussed

- Understanding the nature of hazardous materials: Tank car loaders must have a clear understanding of the materials they handle to identify potential risks and implement appropriate safety measures.

- Proper training and certification: Car loaders should undergo thorough training and obtain necessary certifications to handle hazardous materials safely.

This includes understanding emergency procedures and proper use of safety equipment. - Adhering to proper handling and loading techniques: Tank car loaders must strictly follow established guidelines for loading and unloading hazardous materials to prevent spills, leaks, and other accidents.

- Regular inspection and maintenance of equipment: Regular inspection and maintenance of tank cars and loading equipment are crucial to identify and fix any potential issues that could compromise safety.

- Emergency response plans and drills: Having well-developed emergency response plans and conducting regular drills can ensure that tank car loaders are prepared to handle any unforeseen situations swiftly and effectively.

- Collaboration with regulatory authorities: Tank car loaders must maintain a strong collaboration with regulatory authorities to stay updated on safety regulations, industry best practices, and any changes in protocols.

In essence, implementing safety protocols for tank car loaders in Nigeria’s rail is imperative for the protection of lives, the environment, and the smooth operation of the rail system.

By understanding the nature of hazardous materials, proper training and certification, adherence to handling techniques, regular equipment inspection, emergency response plans, and collaboration with regulatory authorities, safety can be effectively upheld.

Overview of tank car loaders in Nigeria’s rail

Tank car loaders play a crucial role in ensuring the safe transportation of hazardous materials in Nigeria’s rail system.

These professionals are responsible for loading and securing tanks cars that carry flammable, toxic, and corrosive substances.

By adhering to strict safety protocols, they mitigate the risks associated with handling dangerous goods.

Purpose of tank car loaders

The primary purpose of tank car loaders is to facilitate the loading and unloading of bulk liquids or gases.

They ensure proper sealing, venting, and positioning of tank cars to prevent spills, leaks, and other accidents.

These strict protocols are in place to protect both the environment and the people involved in the transportation process.

Role in transporting hazardous materials

Tank car loaders play a critical role in the transportation of hazardous materials in Nigeria’s rail system.

They ensure that the loading and unloading processes are carried out in a safe and controlled manner.

By following the set guidelines and procedures, they reduce the potential for accidents or incidents during transportation.

Statistics on the volume of tank car loading activities in Nigeria

To understand the significance of tank car loading activities in Nigeria, it is important to consider the statistics related to this sector.

According to the Nigerian Railways Corporation, approximately 50% of all hazardous materials transported by rail are loaded in tank cars.

This highlights the substantial volume of tank car loading activities in the country.

The volume of tank car loading activities in Nigeria underscores the importance of safety protocols.

The sheer number of hazardous materials being transported necessitates strict adherence to safety guidelines. This ensures the protection of both workers and communities along the rail routes.

Safety protocols

One of the key safety protocols is the proper inspection of tank cars before loading. This involves checking for any defects or damage that could compromise the integrity of the tank.

Additionally, tank car loaders must ensure that the appropriate equipment, such as hoses and valves, are in good condition and correctly connected.

Tank car loaders must also be trained in handling emergency situations. They need to know how to respond to spills, leaks, or other accidents that may occur during the loading or transportation process.

This includes knowledge of containment measures and the use of personal protective equipment.

Regular maintenance and inspection of the rail infrastructure are also crucial for ensuring safe tank car loading activities.

The tracks must be in good condition to prevent derailments or accidents during transportation. Adequate signage and communication systems should be in place to minimize the risk of collisions or other incidents.

Furthermore, tank car loaders must comply with all relevant regulations and standards set by regulatory bodies such as the Nigerian Railway Corporation and the National Environmental Standards and Regulations Enforcement Agency.

These guidelines govern the handling and transportation of hazardous materials and aim to protect public safety and the environment.

In fact, tank car loaders in Nigeria’s rail system play a vital role in the safe transportation of hazardous materials.

By adhering to strict safety protocols, they help mitigate the risks associated with handling dangerous goods.

The volume of tank car loading activities underscores the need for proper training, equipment maintenance, and adherence to regulatory standards.

These professionals contribute significantly to ensuring the safety of both workers and communities along the rail routes.

Read: Tank Truck Loading in Nigeria: A Day in the Life

Potential risks and hazards involved in tank car loading

Tank car loading is a critical process in the Nigerian rail system, but it also poses potential risks and hazards.

It is important for loaders to be aware of these risks and to follow safety protocols to prevent accidents and protect themselves, the environment, and the public.

Potential Risks and Hazards

- Flammable or explosive materials: Many tank cars transport substances that are highly flammable or explosive, such as petroleum products or chemicals.

Any mishandling of these materials can lead to disastrous consequences. - Toxic materials: Tank cars may also carry toxic substances, which can be harmful if released into the environment or if personnel are exposed to them.

- Pressurized containers: Some tank cars contain pressurized gases or liquids, which can cause explosions or leaks if not handled properly.

Possibility of Leaks or Spills

Improper loading techniques or faulty equipment can lead to leaks or spills during the tank car loading process.

This can result in environmental contamination, damage to infrastructure, and potential harm to nearby communities.

Even small spills can have significant impacts, as they can contaminate soil, water sources, and the air, causing long-term damage to ecosystems and human health.

Exposure to Toxic or Flammable Materials

Tank car loaders are at risk of exposure to toxic or flammable materials during the loading process.

Inhalation, skin contact, or ingestion of these substances can lead to severe health issues, including respiratory problems, burns, or even fatalities.

Proper personal protective equipment (PPE) such as gloves, masks, and goggles must be worn to minimize the risk of exposure and ensure the safety of the loaders and those working in the vicinity.

Health and Environmental Impacts

Accidental spills or leaks from tank cars can have devastating consequences on both human health and the environment.

Toxic chemicals can contaminate water sources, harming aquatic life and potentially entering the food chain.

Flammable materials can ignite and cause fires, posing serious risks to both personnel and nearby communities.

Furthermore, such incidents can have long-lasting effects on the environment, including air pollution and the destruction of ecosystems.

Addressing these risks

To mitigate the risks and ensure the safety of tank car loaders, comprehensive safety protocols should be strictly followed:

- Proper Training: All personnel involved in the tank car loading process must undergo thorough training on safety procedures, emergency response, and the proper handling of hazardous materials.

- Equipment Inspection: Regular inspection and maintenance of loading equipment such as hoses, valves, and connectors are essential to prevent leaks or equipment failure.

- Loading Procedures: Loaders should follow established loading procedures, including monitoring the fill levels, ensuring proper valve closure, and verifying the compatibility of materials being loaded.

- Adequate Ventilation: Adequate ventilation systems, such as exhaust fans, should be in place to prevent the buildup of flammable or toxic vapors during the loading process.

- Emergency Response Plan: A robust emergency response plan must be in place, outlining procedures for immediate action in case of spills, leaks, or any other incidents.

This includes evacuation protocols, communication procedures, and access to emergency response equipment. - Regular Safety Audits: Periodic safety audits should be conducted to assess compliance with safety protocols, identify potential hazards, and address any issues promptly.

In short, safety protocols are crucial to protect tank car loaders and the environment from potential risks and hazards.

Adhering to proper training, maintaining equipment, following loading procedures, providing adequate ventilation, and having an emergency response plan in place are essential in ensuring safe and responsible tank car loading operations in Nigeria’s rail system.

Only by implementing these measures can we minimize accidents, protect human health, and preserve the environment for future generations.

Read: How to Start a Career as a Ship Loader in Nigeria’s Ports

Safety Protocols for Tank Car Loaders in Nigeria’s Rail

Ensuring the safety of tank car loaders is of utmost importance in Nigeria’s rail industry. Here are some key protocols and guidelines to follow:

Safety Protocols and Guidelines for Tank Car Loaders

- Compliance with international safety standards is crucial for tank car loading operations.

- Proper training and certification of personnel involved in tank car loading should be mandatory.

- The use of personal protective equipment (PPE) such as gloves, goggles, and protective clothing is essential.

- Regular maintenance and inspections of tank cars should be conducted to identify and address any potential safety hazards.

Why Compliance with International Safety Standards is Important

- Adhering to international safety standards ensures that tank car loading operations meet global safety requirements.

- It enhances the overall safety and reliability of the rail transportation system in Nigeria.

- Compliance helps protect the environment and prevents accidents or incidents that may lead to hazardous material spills.

- It also improves the reputation of Nigeria’s rail industry, making it more attractive for potential investors.

Proper Training and Certification of Personnel

- All personnel involved in tank car loading must undergo proper training and obtain certifications.

- Training programs should cover topics such as safety precautions, emergency procedures, and handling of hazardous materials.

- Ongoing training should be provided to ensure that personnel stay updated with the latest safety protocols.

- Certification of personnel demonstrates their competence and commitment to maintaining high safety standards.

Use of Personal Protective Equipment (PPE)

- Tank car loaders must wear appropriate PPE, including gloves, goggles, and protective clothing, to minimize the risk of injuries.

- PPE acts as a barrier between the loaders and any hazardous materials that may be present.

- Regular inspection and replacement of PPE should be carried out to ensure its effectiveness.

- Training on the proper use and maintenance of PPE should be provided to all personnel.

Regular Maintenance and Inspections of Tank Cars

- Regular maintenance and inspections of tank cars are crucial for identifying and addressing any potential safety issues.

- Inspections should include checks for leaks, structural integrity, and proper functioning of safety devices.

- Maintenance schedules should be followed to ensure that tank cars are in optimum condition at all times.

- Any defects or damages should be promptly repaired to prevent accidents or incidents during loading operations.

By strictly following these safety protocols, Nigeria’s rail industry can ensure the well-being of tank car loaders and minimize the risks associated with hazardous material transportation.

Read: Nigeria’s Ship Loaders: A Thriving Maritime Career Path

Emergency Response Preparedness

Emergency response preparedness is crucial for tank car loaders in Nigeria’s rail system to effectively handle any unforeseen emergencies.

- Develop a comprehensive emergency response plan that includes step-by-step procedures for different types of emergencies.

- Designate a trained and well-equipped emergency response team responsible for executing the plan.

- Ensure that the emergency response team is adequately trained to handle various emergency situations.

- Conduct regular drills and simulations to test the effectiveness of the emergency response plan.

- Maintain an inventory of emergency response equipment, such as fire extinguishers, containment booms, and personal protective gear.

Implementation of Contingency Plans

Implementing contingency plans is essential to minimize the impact of emergencies and protect lives, the environment, and infrastructure.

- Create contingency plans that outline specific actions to be taken in the event of different emergency scenarios.

- Identify potential hazards and vulnerabilities at loading sites and develop strategies to mitigate them.

- Ensure that all personnel involved in tank car loading are familiar with contingency plans and their respective roles.

- Regularly review and update contingency plans to reflect any changes in the operation or external environment.

- Collaborate with relevant government agencies, local communities, and emergency responders to align contingency plans.

Communication Protocols During Emergencies

Establishing effective communication protocols during emergencies is crucial to ensure timely response and coordination among all stakeholders.

- Designate a central communication point with dedicated personnel to receive and disseminate emergency information.

- Ensure that all personnel involved in tank car loading are aware of the communication protocols and contact information.

- Implement redundant communication systems, such as landlines, mobile phones, radios, and satellite communication.

- Regularly test the communication systems to ensure their reliability and troubleshoot any issues.

- Establish protocols for reporting emergencies to the appropriate authorities and stakeholders.

Training for Handling Emergencies and Spills

Proper training for handling emergencies and spills equips tank car loaders with the necessary skills to respond effectively and minimize damages.

- Provide comprehensive training on emergency response procedures, spill containment techniques, and hazardous material handling.

- Ensure that all tank car loaders receive regular training updates to stay informed about the latest practices and regulations.

- Conduct practical exercises to familiarize personnel with spill response equipment and facilitate hands-on learning.

- Collaborate with industry associations and regulatory bodies to provide specialized training programs for tank car loaders.

- Evaluate the effectiveness of training programs through continuous assessment and feedback from personnel.

Read: A Guide to Truck Loading Jobs in Nigeria’s Oil Industry

Monitoring and Enforcement of Safety Protocols

Regular monitoring of tank car loading facilities is essential to ensure compliance with safety protocols.

Train operators should be vigilant in identifying any lapses in safety procedures during the loading process.

A dedicated team should be appointed to consistently enforce safety protocols and address any violations promptly.

Monitoring and enforcement should include regular inspections, audits, and training programs for tank car loaders.

Routine checks should be conducted to ensure that safety equipment such as fire extinguishers, protective gear, and emergency alarms are functional.

Continuous supervision is crucial to identify and rectify any potential risks or hazards during the loading process.

Role of Regulatory Agencies and Government Bodies

- Regulatory agencies play a vital role in setting and enforcing safety standards for tank car loading.

- These agencies should collaborate with government bodies to develop stringent regulations that prioritize safety.

- Government bodies must provide the necessary resources and support to regulatory agencies to effectively carry out their duties.

- Regulatory agencies should conduct regular inspections and audits to ensure compliance with safety protocols.

- These agencies should also be responsible for providing appropriate training and certifications to tank car loaders.

- Collaboration between regulatory agencies, government bodies, and industry stakeholders is essential for comprehensive safety measures.

Inspections and Audits of Tank Car Loading Facilities

- Regular inspections of tank car loading facilities are vital to identify and rectify any safety hazards.

- Inspections should cover various aspects, including equipment, procedures, employee training, and emergency response plans.

- Audits should be conducted to assess compliance with safety protocols and determine areas for improvement.

- Inspection reports should be promptly reviewed, and necessary actions must be taken to address any identified issues.

- Unannounced inspections can be conducted to ensure continuous adherence to safety regulations without any potential biases.

- Inspections and audits should be carried out by experienced professionals with a thorough understanding of tank car loading operations.

Consequences for Non-Compliance with Safety Regulations

- Non-compliance with safety regulations should result in strict penalties and legal consequences.

- Violators should face fines, license suspensions, or even legal action depending on the severity of the offense.

- Repeat offenders should face harsher penalties to deter non-compliance and ensure adherence to safety protocols.

- Companies and individuals responsible for safety violations should be held accountable for any resulting accidents or damages.

- Non-compliance should also lead to mandatory retraining and education on safety protocols for offenders.

- Public awareness campaigns should emphasize the importance of safety protocols and the consequences of non-compliance.

Case Studies and Success Stories

When it comes to safety protocols for tank car loaders in Nigeria’s rail, there are several case studies and success stories that highlight the importance of implementing strict safety measures.

These success stories serve as examples of tank car loading facilities with exemplary safety records, showcasing the positive impact of following safety protocols.

- MRS Petroleum: MRS Petroleum is a leading oil and gas company in Nigeria that has implemented robust safety protocols for tank car loading.

By conducting regular safety audits, providing comprehensive training to employees, and enforcing strict safety guidelines, MRS Petroleum has achieved an impressive safety record. - Mobil Chemicals: Mobil Chemicals specializes in the transportation of hazardous chemicals through tank cars

Through proactive safety measures, such as regular maintenance of equipment, strict monitoring of loading and unloading processes, and adherence to industry regulations, ABC Chemicals has consistently ensured the safety of their operations.

Examples of Tank Car Loading Facilities with Exemplary Safety Records

- NNPC Depot: The Nigerian National Petroleum Corporation (NNPC) Depot in Lagos is renowned for its exemplary safety record.

The facility follows stringent safety protocols, including regular equipment inspections, safety training for employees, and constant monitoring of loading procedures. - Dangote Refinery: Dangote Refinery, one of the largest refineries in Africa, sets a high standard for safety in tank car loading.

The facility ensures the use of state-of-the-art equipment, employs highly trained operators, and maintains a strict safety culture, resulting in an impeccable safety track record.

Positive Impact of Implementing Safety Protocols

Implementing safety protocols for tank car loaders in Nigeria’s rail system has numerous positive impacts, including:

- Enhanced Safety: Following strict safety protocols reduces the risk of accidents, ensuring the well-being of employees and the surrounding communities.

- Operational Efficiency: Proper safety measures streamline loading processes, minimizing downtime and maximizing efficiency in rail operations.

- Reputation and Trust: Companies with exemplary safety records gain the trust of clients, regulatory bodies, and the public, enhancing their reputation in the industry.

- Cost Savings: Avoiding accidents and incidents through safety protocols saves companies from costly legal battles, fines, and reputation damage.

- Compliance with Regulations: Adhering to safety protocols ensures compliance with industry regulations and strengthens the overall integrity of the rail system.

- Environmental Protection: Strict safety measures mitigate the risk of spills or leaks, protecting the environment and preventing ecological damage.

basically, safety protocols for tank car loaders in Nigeria’s rail system are crucial to ensure the well-being of employees, protect the environment, and maintain operational efficiency.

Case studies and success stories highlight the importance of implementing strict safety measures, and examples of tank car loading facilities with exemplary safety records serve as models to be followed.

The positive impact of following safety protocols includes enhanced safety, operational efficiency, reputation building, cost savings, regulatory compliance, and environmental protection.

By prioritizing safety, Nigeria’s rail system can continue to improve and provide efficient and secure transportation of goods.

Conclusion

Safety protocols for tank car loaders in Nigeria’s rail are crucial for preventing accidents and ensuring the well-being of workers.

Safety must be prioritized at all times during the loading operations to mitigate any risks or hazards.

Recap of the importance of safety protocols

Throughout this blog chapter, we have emphasized the significance of safety protocols in tank car loading operations in Nigeria’s rail.

These protocols are necessary to protect workers, prevent accidents, and ensure the efficient transportation of hazardous materials.

Call to action for increased focus on safety

It is imperative for all stakeholders involved in tank car loading operations to increase their focus on safety. This includes the railway authorities, tank car loaders, and regulatory bodies.

By strictly adhering to safety protocols, we can work towards a safer and more secure rail transportation system.

Final thoughts and recommendations

In order to enhance safety in tank car loading operations, it is recommended that regular training sessions be conducted for tank car loaders.

These sessions should cover the latest safety protocols, emergency procedures, and best practices.

Additionally, implementing technology such as monitoring systems and automated safety features can further enhance the safety of tank car loading operations.

Safety protocols in tank car loading operations are vital for the well-being of workers and the prevention of accidents.

It is crucial for all stakeholders to actively prioritize and enforce these protocols to ensure a safe and secure rail transportation system in Nigeria.

By doing so, we can safeguard both human lives and the environment from potential hazards and risks.