Introduction

Nigeria’s manufacturing sector holds a pivotal position in the nation’s economic advancement. This article delves into the transformative potential of robotics within this industry.

Nigeria’s manufacturing industry is a linchpin of its economic development. It contributes significantly to GDP and employment, driving progress across various sectors.

The integration of robotics marks a pivotal juncture in the evolution of Nigeria’s manufacturing landscape.

By harnessing automated technologies, industries can unlock heightened productivity, streamlined operations, and enhanced efficiency.

Robotic systems offer precision, scalability, and consistency, revolutionizing production processes.

They reduce manual labor, minimize errors, and facilitate mass customization, empowering Nigerian manufacturers to compete effectively on a global scale.

Recognizing the role of robotics in Nigeria’s manufacturing realm is imperative for sustainable growth.

Embracing these technological advancements can propel the nation towards industrial excellence, fostering economic prosperity and securing a formidable global stance.

Historical Perspective

Evolution of manufacturing in Nigeria

- Nigeria’s manufacturing industry has witnessed significant growth and transformation over the years.

- Initially, manufacturing in Nigeria was centered around agriculture and small-scale industries.

- With the discovery of oil in the 1970s, Nigeria’s focus shifted from manufacturing to the oil sector.

- This resulted in a decline in manufacturing activities and a heavy dependence on oil exports.

- In recent years, there has been a renewed interest in revitalizing the manufacturing sector to diversify the economy.

- Efforts have been made to promote local production, attract foreign investment, and develop industrial clusters.

- Various industries including textiles, automotive, and food processing have emerged and contributed to economic growth.

Challenges faced by the industry

- Despite progress, the manufacturing industry in Nigeria faces several challenges.

- Inadequate infrastructure, including power supply, transportation, and logistics, hinders efficient production.

- Limited access to affordable finance constrains investment in modern technologies and equipment.

- High cost of production, due to factors such as expensive raw materials and inefficient processes, affects competitiveness.

- Insufficient skilled labor and low productivity levels pose challenges to the industry’s growth.

- Inconsistent government policies, corruption, and bureaucratic processes create uncertainties for manufacturers.

- These challenges have resulted in a decline in the industry’s contribution to the country’s GDP.

Need for automation and robotics

- To address the challenges faced by Nigeria’s manufacturing industry, automation and robotics play a crucial role.

- Automation enables increased productivity, efficiency, and cost reduction in manufacturing processes.

- Robotics, with its precision and accuracy, can improve product quality and consistency.

- Implementing automation and robotics allows manufacturers to streamline operations and reduce human errors.

- Automated systems can handle repetitive and strenuous tasks, reducing the need for manual labor.

- This can help overcome the shortage of skilled labor and improve overall productivity levels.

- Furthermore, automation and robotics enable manufacturers to adapt to changing market demands quickly.

- By embracing these technologies, the manufacturing industry in Nigeria can become more competitive globally.

- Automation and robotics also contribute to job creation, as skilled workers are needed to operate and maintain these systems.

- Additionally, the adoption of automation and robotics aligns with Nigeria’s vision of becoming an industrialized nation.

In short, Nigeria’s manufacturing industry has evolved over the years, facing various challenges along the way.

The need for automation and robotics arises from the industry’s strive for increased productivity, efficiency, and competitiveness.

By embracing these technologies, Nigeria can overcome the limitations it faces and pave the way for a robust and sustainable manufacturing sector.

Importance of Robotics in Nigeria’s Manufacturing Industry

Increased efficiency and productivity

- Robotics in Nigeria’s manufacturing industry can lead to increased efficiency through automation of repetitive tasks.

- Robots can work faster and more accurately than humans, resulting in higher productivity levels.

- With robotics, manufacturers can streamline their processes, reducing wastage and maximizing output.

- Increased efficiency and productivity help businesses meet demand and deadlines more effectively.

Improved quality control and precision

- Robots can consistently perform tasks with a higher level of precision than humans.

- They can maintain specific parameters and standards, ensuring products meet quality requirements.

- Automated systems can detect defects and malfunctions quickly, reducing errors and minimizing rejections.

- Improved quality control leads to enhanced customer satisfaction and loyalty.

Reduction of labor costs and increased competitiveness

- By employing robots, manufacturers can reduce their dependence on manual labor.

- Robots can work continuously without breaks, eliminating the need for shift rotations and associated costs.

- Automation reduces labor costs in the long run, as robots require minimal maintenance compared to human employees.

- As labor costs decrease, manufacturers can offer competitive pricing and gain a competitive advantage.

- Increased competitiveness enables Nigerian manufacturers to compete on a global scale and expand their market reach.

In a nutshell, robotics plays a crucial role in Nigeria’s manufacturing industry.

Its importance can be summarized through increased efficiency and productivity, improved quality control and precision, as well as the reduction of labor costs and increased competitiveness.

By embracing robotics, Nigerian manufacturers can revolutionize their operations and remain at the forefront of technological advancements in the global market.

Read: Universities Offering Robotics Engineering in Nigeria

Adoption of Robotics in Nigeria

Current state of robotics implementation

- Limited implementation of robotics technology in Nigeria’s manufacturing industry.

- Majority of manufacturing processes are still carried out manually, resulting in inefficiencies.

- Lack of awareness and understanding about the benefits of robotics hinders its adoption.

- Some companies have started integrating robotics but at a very limited scale.

- Few industries, such as automotive and electronics, have embraced robotics to improve productivity.

- Overall, Nigeria lags behind other countries in terms of robotics implementation in manufacturing.

Challenges hindering adoption

- High cost of acquiring and maintaining robotics technology is a major hindrance.

- Limited access to financing options for businesses looking to invest in robotics.

- Lack of skilled workforce with expertise in robotics technology and programming.

- Poor infrastructure, such as unreliable power supply, poses challenges for running robotics systems.

- Resistance to change and fear of job loss among workers prevent widespread adoption.

Potential solutions for widespread adoption

- Government support through subsidies and grants to reduce the cost of robotics technology.

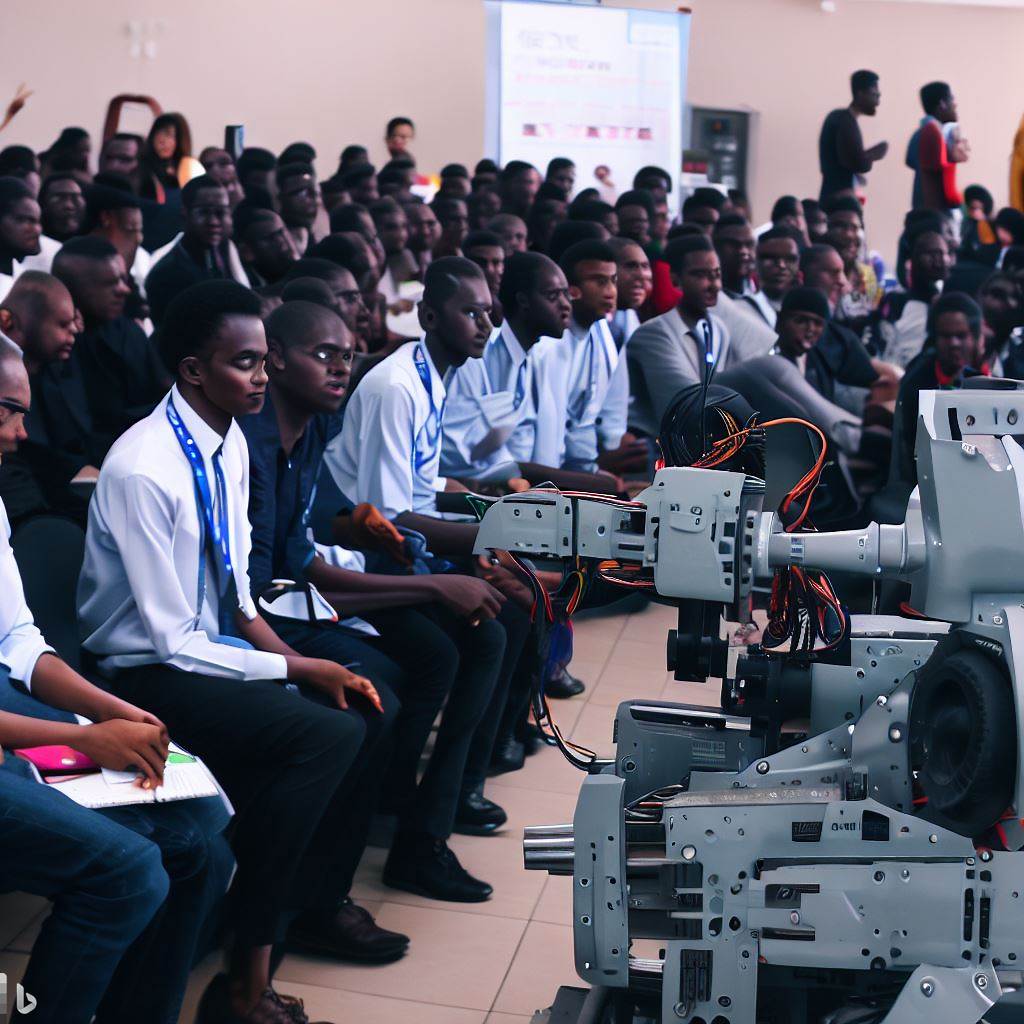

- Collaboration between government, industry, and academia to develop robotics education programs.

- Encouraging partnerships between local and international robotics companies to transfer knowledge.

- Investment in improving infrastructure, especially reliable power supply, to support robotics implementation.

- Creating awareness campaigns to educate businesses and workers about the benefits of robotics.

- Establishing technical training centers to develop a skilled workforce in robotics technology.

- Phasing in robotics technology gradually, allowing employees to adapt and acquire new skills.

Most importantly, Nigeria’s manufacturing industry has a long way to go in terms of adopting robotics.

While there are a few industries that have embraced this technology, the overall implementation is limited.

Challenges such as high costs, lack of skilled workforce, and poor infrastructure hinder the adoption process.

However, potential solutions such as government support, collaboration, and investment in infrastructure can drive widespread adoption.

By addressing these challenges and implementing the suggested solutions, Nigeria can unlock the benefits of robotics in its manufacturing industry and improve productivity.

Role of Government and Policy

In order to foster the growth of robotics in Nigeria’s manufacturing industry, the government plays a crucial role by implementing various initiatives and policies.

These measures aim to encourage businesses to embrace robotics technology and ensure the sector’s overall development.

Government initiatives and programs promoting robotics in manufacturing

The Nigerian government understands the immense potential of robotics in enhancing the efficiency and productivity of the manufacturing industry.

In line with this, they have introduced several initiatives and programs to promote the adoption of robotics technology.

One such initiative is the establishment of specialized training centers and institutes that offer courses related to robotics and automation.

These centers provide the necessary technical skills and knowledge required for individuals to work in the robotics field.

By providing a skilled workforce, the government aims to attract investment and drive innovation in manufacturing.

Furthermore, the government has partnered with industry experts and research institutions to develop research and development (R&D) programs in the field of robotics.

These programs focus on creating innovative solutions to address the specific needs of the manufacturing industry.

Additionally, the government has initiated collaborations with international organizations and countries that have advanced robotics capabilities.

Through these collaborations, knowledge and expertise are shared, and Nigeria benefits from the best practices and experiences of these countries.

Incentives for businesses to invest in robotics technology

Incentivizing businesses to invest in robotics technology is crucial for the rapid adoption and expansion of robotics in Nigeria’s manufacturing sector.

The government has introduced various incentives to encourage businesses to embrace this technology.

Firstly, the government provides tax incentives and exemptions for companies that invest in robotics and automation.

These tax benefits help businesses reduce their overall costs and make the investment in robotics technology more attractive.

Secondly, the government offers financial support in the form of grants and subsidies to businesses that demonstrate a commitment to incorporating robotics in their manufacturing processes.

These financial incentives ease the financial burden associated with technology adoption and encourage investment.

Moreover, the government has implemented policies that prioritize companies using robotics technology in public procurement processes.

This preference for businesses utilizing robotics not only creates a demand for such technology but also encourages its widespread adoption.

Furthermore, the government has established regulatory frameworks that promote the safe and ethical use of robotics in manufacturing.

These regulations ensure that businesses adhere to the necessary standards and guidelines, thereby fostering a secure and responsible environment for the deployment of robotics technology.

Lastly, the Nigerian government plays a vital role in promoting robotics in the manufacturing industry through various initiatives and policies.

By actively supporting training programs, research collaborations, and providing incentives, the government encourages businesses to invest in robotics technology.

These efforts contribute to the growth and development of the manufacturing sector, facilitating increased efficiency and competitiveness in Nigerian industries.

Read: How Robotics Is Transforming the Nigerian Oil Industry

Impact on Workforce

The introduction of robotics in Nigeria’s manufacturing industry has brought significant impacts on the workforce.

While there are concerns regarding job displacement and unemployment, there are also opportunities for upskilling and retraining, as well as collaboration potential between humans and robots.

Concerns regarding job displacement and unemployment

One of the major concerns surrounding the use of robotics in Nigeria’s manufacturing industry is the fear of job displacement and increased unemployment.

As advanced automation takes over certain tasks previously performed by humans, there is a legitimate concern that many workers may lose their jobs.

Companies implementing robotics often prioritize efficiency and cost-effectiveness, leading to a reduction in the number of human workers required.

As a result, individuals who were once employed in the manufacturing sector may face unemployment or find it challenging to secure new job opportunities.

However, it is important to note that job displacement is not unique to robotics, and technological advancements have historically led to the creation of new industries and job roles.

While certain positions may become redundant, new jobs are likely to emerge in areas such as robot maintenance, programming, and supervision.

Opportunities for upskilling and retraining

Despite concerns surrounding job displacement, the introduction of robotics in Nigeria’s manufacturing industry can also create opportunities for upskilling and retraining the workforce.

As automation takes over repetitive and mundane tasks, workers can focus on developing new skills and expanding their knowledge.

With the right training programs and investments in human capital, workers previously engaged in routine tasks can transition into more complex and higher-value roles.

For instance, they can learn how to operate and maintain the robotic systems or specialize in tasks that require creativity, problem-solving, and critical thinking.

Upskilling and retraining initiatives not only address the potential unemployment crisis but also contribute to workforce development and empower individuals with versatile skills that are in demand in the modern job market.

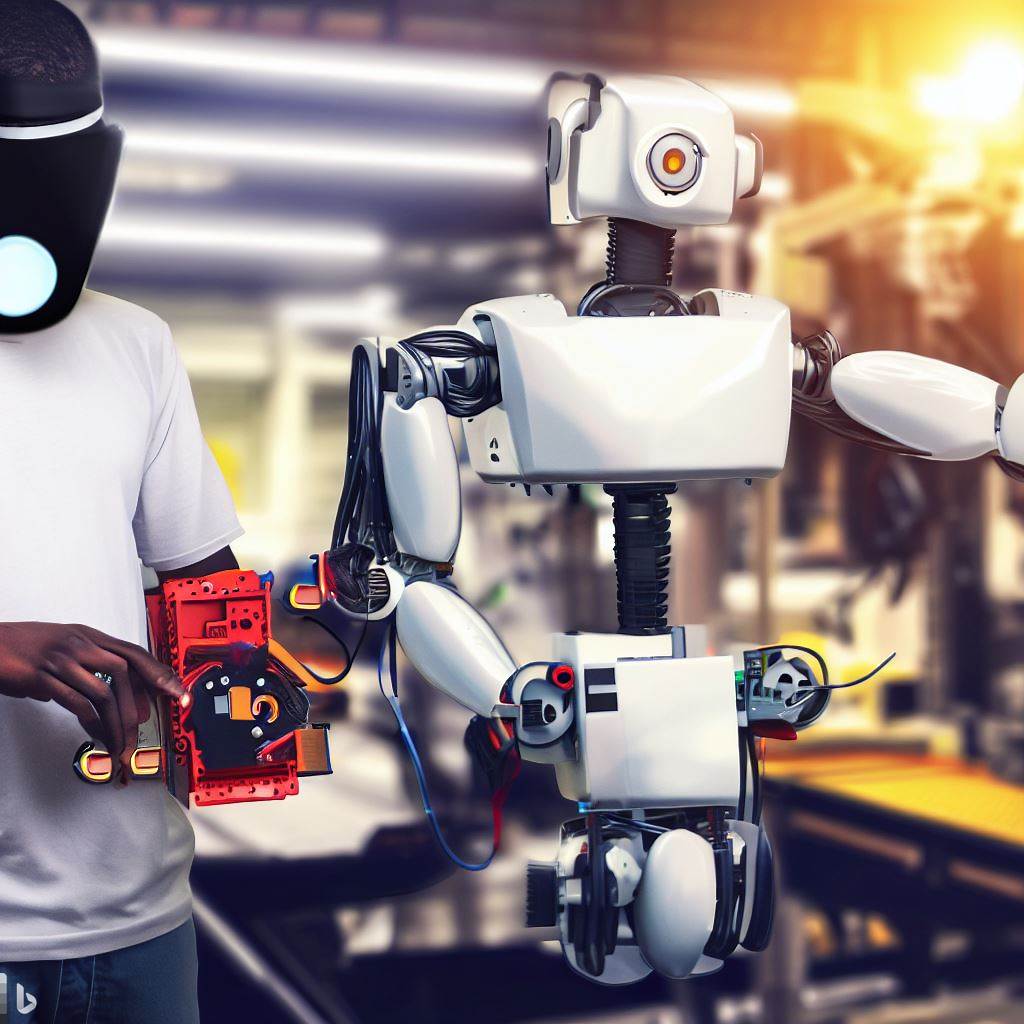

Collaboration potential between humans and robots

Another crucial aspect to consider is the collaboration potential between humans and robots in Nigeria’s manufacturing industry.

Rather than completely replacing human workers, robots can complement their skills and capabilities, leading to enhanced productivity and efficiency.

Robots excel in tasks that require precision, speed, and repetitive actions, whereas humans have unique cognitive abilities and emotional intelligence.

By working together, humans and robots can create a harmonious and efficient production environment.

Collaboration between humans and robots also opens avenues for innovation.

For instance, human workers can provide insights and ideas for process improvement, while robots can execute these tasks accurately and reliably.

This collaboration can result in better product quality and increased overall competitiveness in the manufacturing sector.

By working alongside robots, human employees can focus on more fulfilling and value-driven work, such as customer service, innovation, and decision-making.

This shift in job roles can lead to improved job satisfaction and quality of work life for individuals employed in the manufacturing industry.

In fact, the introduction of robotics in Nigeria’s manufacturing industry brings both concerns and opportunities for the workforce.

While job displacement and unemployment remain concerns, there are also opportunities for upskilling, retraining, and collaboration between humans and robots.

By embracing these opportunities and investing in the workforce, Nigeria can harness the potential of robotics to drive economic growth, create new jobs, and improve overall productivity in the manufacturing industry.

Read: Success Stories of Notable Nigerian Petroleum Engineers

Case Studies

Highlight successful implementation of robotics in Nigerian manufacturing companies

- Dangote Industries: Dangote, a prominent Nigerian conglomerate, embraced robotics to enhance its manufacturing processes. By deploying robots in their cement production plants, they achieved higher efficiency and quality control.

- Procter & Gamble: Procter & Gamble, a global consumer goods company, introduced robotics in their Nigerian manufacturing facilities. Robots were used for packaging and assembly tasks, resulting in faster production and reduced errors.

- Innoson Vehicle Manufacturing Company: Innoson, a Nigerian automobile manufacturer, integrated robotics into their assembly line. This investment enabled them to increase production capacity, improve precision, and meet market demands more effectively.

Discuss outcomes and benefits achieved

- Increased productivity: Nigerian manufacturing companies witnessed a significant boost in productivity after implementing robotics. Automation allowed for faster and more accurate completion of tasks, leading to increased output.

- Improved product quality: With robots taking over repetitive and demanding tasks, human errors decreased, ultimately enhancing the quality of products manufactured. This led to greater customer satisfaction and improved brand reputation.

- Enhanced safety: Robotics provide a safer working environment by replacing humans in hazardous operations. Nigerian manufacturing companies experienced a reduction in workplace accidents, ensuring the well-being of their employees.

- Cost savings: Despite the initial investment required for robotics implementation, Nigerian companies achieved long-term cost savings. Robots reduce labor costs by performing tasks more efficiently, minimizing production downtime, and decreasing the need for rework.

- Competitive advantage: By adopting robotics, Nigerian manufacturing companies gained a competitive edge in the market. Increased productivity, improved quality, and cost savings allowed them to offer products at competitive prices while maintaining profitability.

- Skill development: Embracing robotics in the manufacturing industry promotes skill development among Nigerian workers. Employees are trained to work alongside robots, acquire new technical skills, and adapt to advanced manufacturing processes.

- Job creation: Contrary to popular belief, the integration of robotics in the Nigerian manufacturing industry has not resulted in significant job losses. Instead, it has led to the creation of new job opportunities in robot programming, maintenance, and supervision.

- Sustainable growth: Robotics contribute to sustainable growth in the Nigerian manufacturing industry by reducing the ecological footprint. Energy-efficient robots optimize resource consumption, minimize waste, and support environmentally friendly practices.

All in all, the successful implementation of robotics in Nigerian manufacturing companies has yielded numerous benefits.

Increased productivity, improved product quality, enhanced safety, and cost savings have propelled these companies to new heights.

Additionally, robotics have fostered skill development, created job opportunities, and facilitated sustainable growth. It is evident that robotics play a vital role in shaping the future of Nigeria’s manufacturing industry.

Read: Emerging Tech Trends for Petroleum Engineers in Nigeria

Future Outlook and Potential

Growth prospects for robotics in Nigeria’s manufacturing industry

- Nigeria’s manufacturing industry has immense potential for growth in the robotics sector.

- The government’s initiatives to promote technological advancements can drive the adoption of robotics.

- Automation can help overcome challenges such as inadequate skilled labor and high production costs.

- Increased efficiency, higher productivity, and improved quality control are some benefits robotics can offer.

- With the push towards industrialization, the demand for robotics is expected to rise significantly.

- The transition to using robotics will attract global investments and boost the manufacturing sector’s competitiveness.

- Investments in robotic technologies will create job opportunities and drive economic growth in Nigeria.

Potential role in diversifying the economy

- Nigeria’s economy is heavily dependent on oil, making it vulnerable to fluctuations in oil prices.

- The adoption of robotics in the manufacturing industry can help diversify Nigeria’s economy.

- By reducing reliance on oil, Nigeria can build a strong and sustainable economy.

- The manufacturing sector, powered by robotics, can contribute to the GDP, export earnings, and job creation.

- Diversification will increase economic resilience and mitigate the risks associated with a single-sector economy.

- Robotics can encourage the development of new industries, such as electronics and advanced manufacturing.

- Embracing robotics will attract foreign direct investment, technology transfer, and knowledge sharing.

Collaboration opportunities for research and development

- Collaboration between the government, academia, and industry is crucial for the development of robotics in Nigeria.

- Joint research and development initiatives can drive innovation and address specific industry challenges.

- Collaboration with international organizations and institutions can promote knowledge exchange and capacity building.

- Partnerships with established robotics companies can facilitate technology transfer and accelerate implementation.

- Joint ventures between Nigerian manufacturing firms and robotics manufacturers can foster local production and assembly.

- Research and development collaborations can focus on adapting robotics to local needs and industries.

- Engaging with robotic experts, engineers, and programmers can enhance Nigeria’s technical capabilities.

In general, Nigeria’s manufacturing industry has a promising future with the integration of robotics.

The growth prospects are significant, offering increased efficiency, productivity, and competitiveness.

Embracing robotics will also contribute to diversifying Nigeria’s economy, reducing dependence on oil.

Collaboration opportunities for research and development will play a crucial role in driving innovation and building technical expertise.

With the right investments, partnerships, and initiatives, Nigeria can leverage robotics to transform its manufacturing industry and pave the way for economic prosperity.

Read: Local Vs International Opportunities for Nigerian Robotics Engineers

Conclusion

The role of robotics in Nigeria’s manufacturing industry is undeniably significant.

This technology has emerged as a pivotal force, amplifying efficiency and productivity within the sector.

As global competition intensifies, it becomes imperative for Nigerian manufacturers to not only recognize but also actively embrace the potential of robotics.

By doing so, they can ensure their sustained relevance and competitiveness on the international stage.

Therefore, it is strongly encouraged that the manufacturing sector in Nigeria continues its exploration and swift adoption of robotics.

This strategic move will not only fortify local industries but also propel the nation toward a prosperous and progressive future in the global manufacturing landscape.

Publish Your Professional Profile, Business or Brand

Showcase your expertise, gain trust, and boost visibility instantly on Professions.ng.

Publish Now